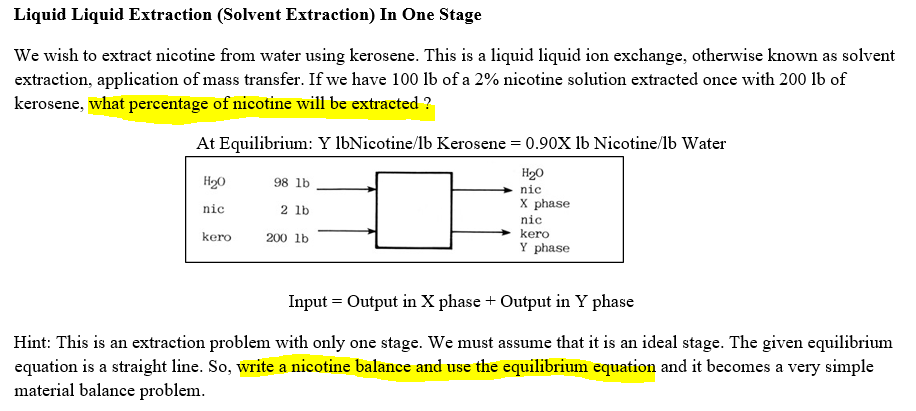

Liquid Liquid Extraction Applications

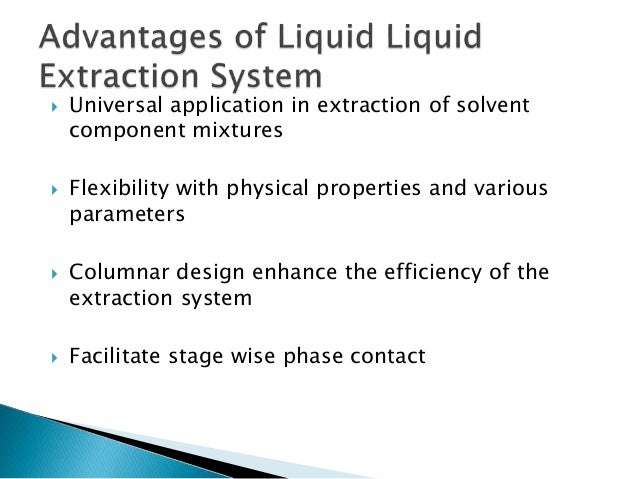

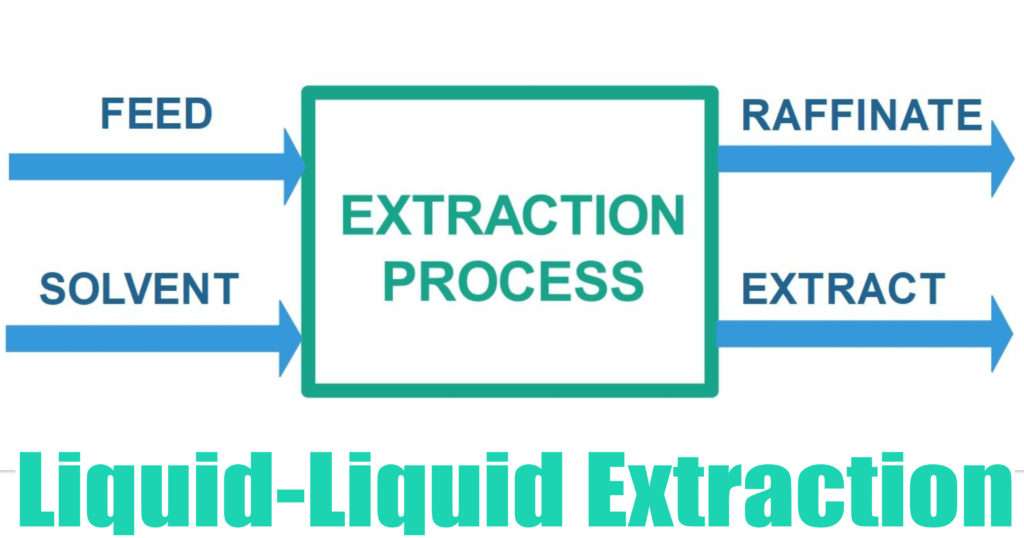

Liquid liquid extraction also known as solvent extraction and partitioning is a method to separate compounds or metal complexes based on their relative solubilities in two different immiscible liquids usually water and an organic solvent.

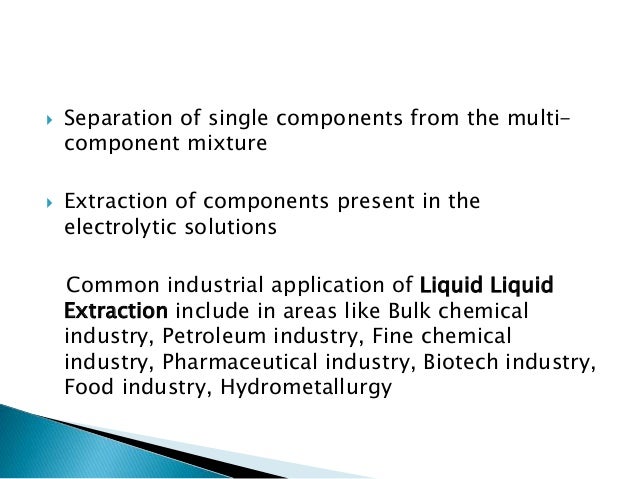

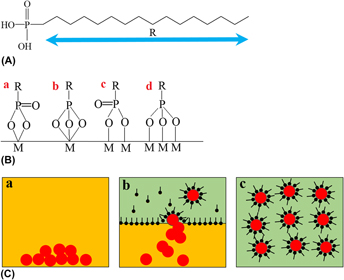

Liquid liquid extraction applications. The pharmaceutical industry. Once the transfer is complete the overall system of chemical components. For these reasons the ligand is added to the organic solvent instead of the aqueous phase. One important application of a liquid liquid extraction is the selective extraction of metal ions using an organic ligand.

Liquid liquid extraction sometimes also called solvent extraction is an important separation technology for a variety of applications in the chemical process industry including the petrochemical food pharmaceutical and metal industries. Biofuels and chemicals produced by biological processes such as fermentation and algae often require liquid liquid extraction lle as the first step in recovery and purification. Liquid liquid extraction for biotechnology extraction of valuable products from fermentation broth. This separation technique also known as solvent extraction has many successful applications in the pharmaceutical industry because of its inherent flexibility and its suitability for processing heat sensitive products.

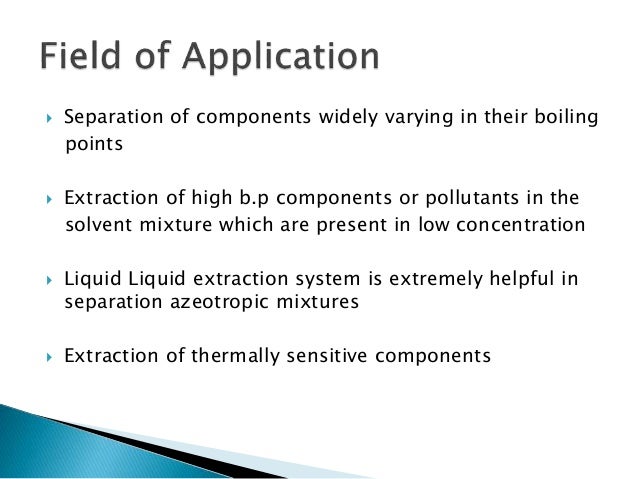

Unfortunately many organic ligands are not very soluble in water or undergo hydrolysis or oxidation reactions in aqueous solutions. Recovery of tightly hydrogen bonded organics from water such as formaldehyde formic acid and acetic acid. The transfer is driven by chemical potential i e. Liquid liquid or solvent extraction is a countercurrent separation process for isolating the constituents of a liquid mixture.

Aliphatic aromatic naphthenic rather than by molecular weight or vapour pressure. Farming and agriculture have been important industries in the united states for many years with their. Many of these chemicals are higher boiling than water or form azeotropes resulting in high energy requirement for distillation. There is a net transfer of one or more species from one liquid into another liquid phase generally from aqueous to organic.

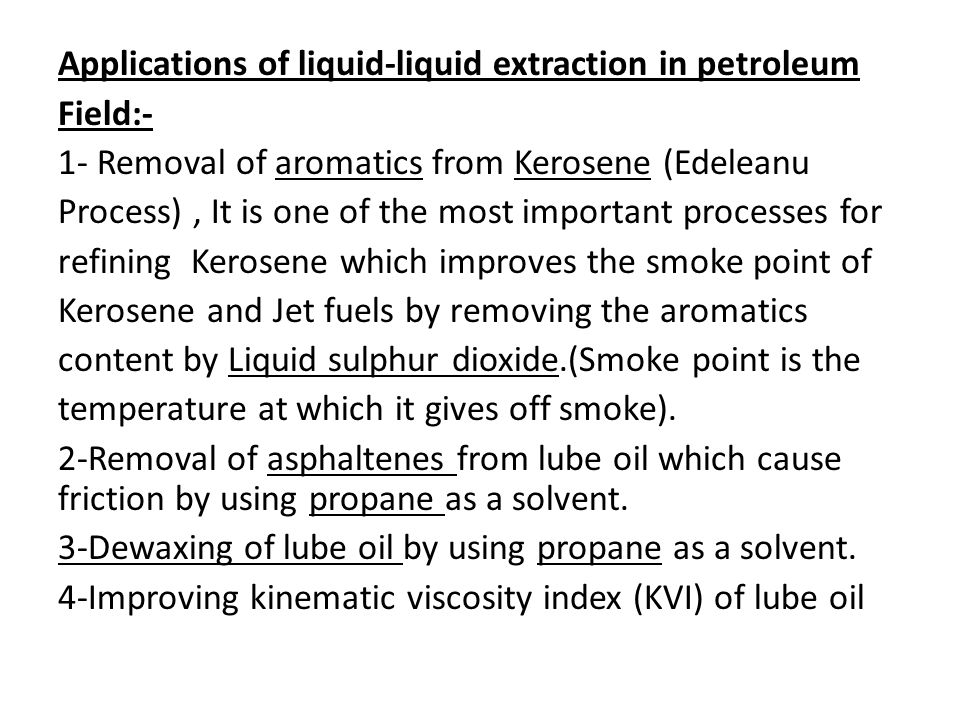

Application of liquid liquid extraction extraction processes are well suited to the petroleum industry because of the need to separate heat sensitive liquid feeds according to chemical type e g. Similar to its use in the agriculture industry the food safety industry uses liquid liquid extractions and.