Rockwell Hardness Test Lab Report

Both ball or diamond cone types of indenters are used in this test.

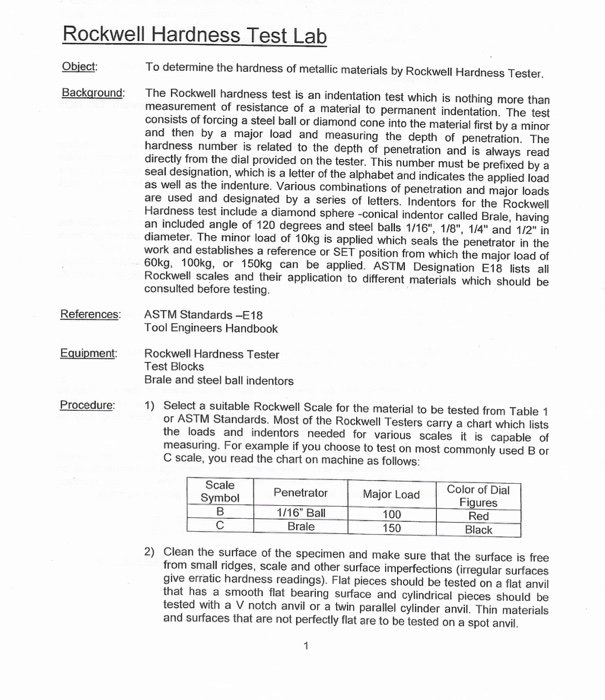

Rockwell hardness test lab report. The b scale uses the spherical steel penetrator and the c scale uses the diamond cone shaped penetrator. Department of engineering swarthmore college. Ea increase in depth of penetration due to major load. The indenter of hardened steel ball or diamond cone can be uses in the rockwell test.

The depth of penetration is inversely proportional to the hardness. Academia edu is a platform for academics to share research papers. The rockwell hardness test consists of many different scales for a range of different hardnesses. There are three scales on the machine for taking hardness readings.

The b and c scales are the types used in this experiment. The hardness of a material by this rockwell hardness test method is measured by the depth of penetration of the indenter. For these reasons the hardness test is used extensively in industry for quality control. 1 the light switch is switched on at the right lower side of the frame after connecting thepower supply to the electric source so that an image on the projection screen is visible clearly.

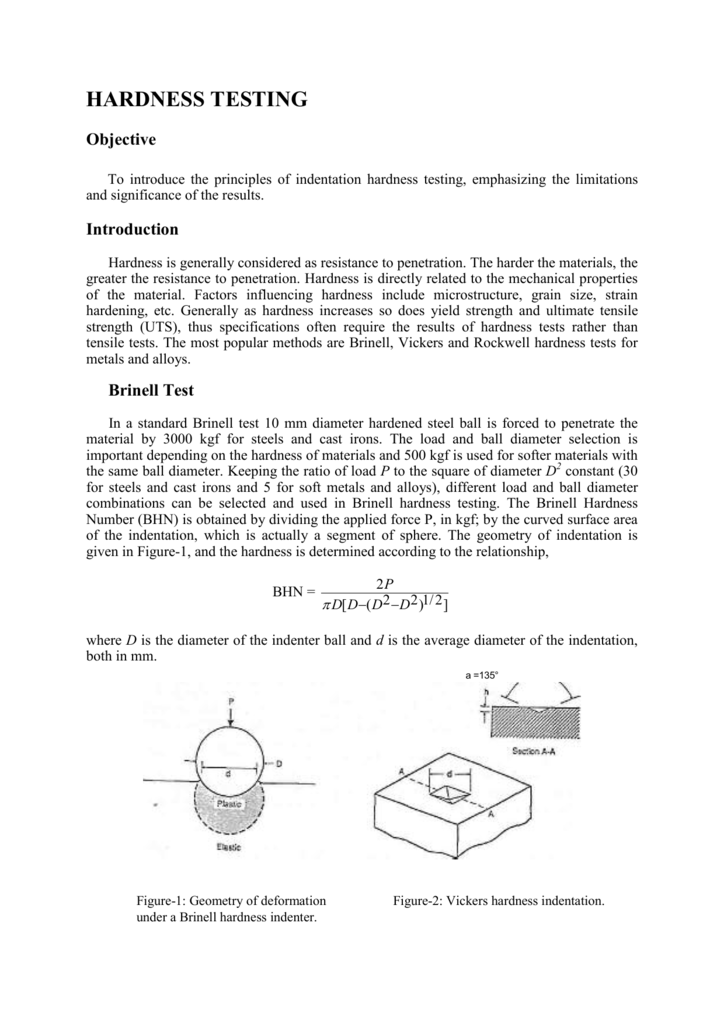

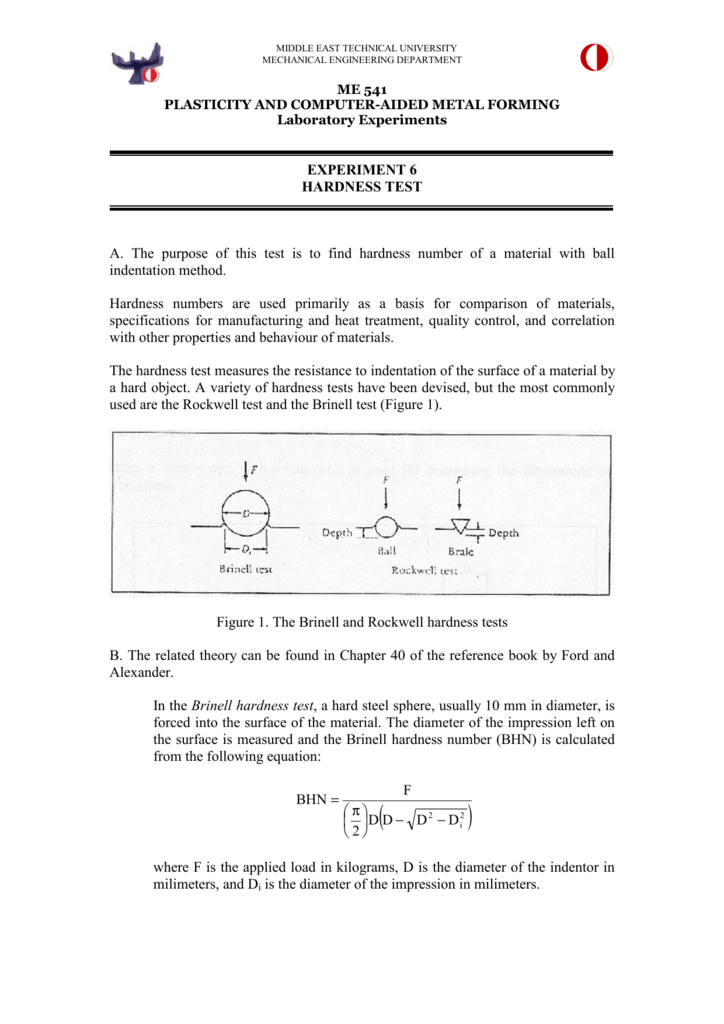

The rockwell hardness is derived from the measurement of the depth of the impression ep depth of penetration due to minor load of 98 07 n. In this lab rockwell hardness tests were performed on two unknown steel specimens and one unknown brass specimen with the intent of identifying the metals. The rockwell test differs from the brinell and vickers tests is not obtaining a value for the hardness in terms of an indentation but using the depth of indentation this depth being directly indicated by a pointer on a calibrated scale. To check record the brinell hardness bhn of specimen sample castings after annealing.

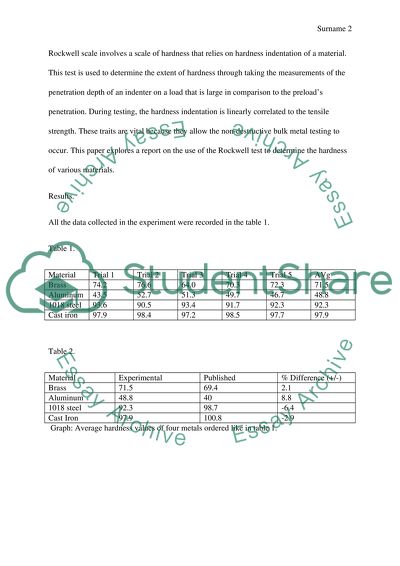

The brinell hardness test can be applied to almost any metallic materia l and is the method most commonly used to test castings and forgings that have a grain structure too coarse for other types of metal hardness testing. The results of our experiment shown in table 1 below correlated to several possible compositions for the unknown steel specimens and one likely composition for the brass specimen. I have used rockwell vickers hardness testing techniques also in some cases to check the hardness of sample castings. The rockwell hardness test method consists of indenting the test material with a diamond come or hardened steel ball indenter.

Vickers and rockwell hardness test the results are given to students in the class lab by the qness hardness test machine in fig. 2 an indenter is chosen and placed into the hole of main rod according to the requirement of the test. Aluminum alloy carbon steel brass commercial pure copper brass and stainless steel etc.