Tensile Test Lab Report Uitm

Academia edu is a platform for academics to share research papers.

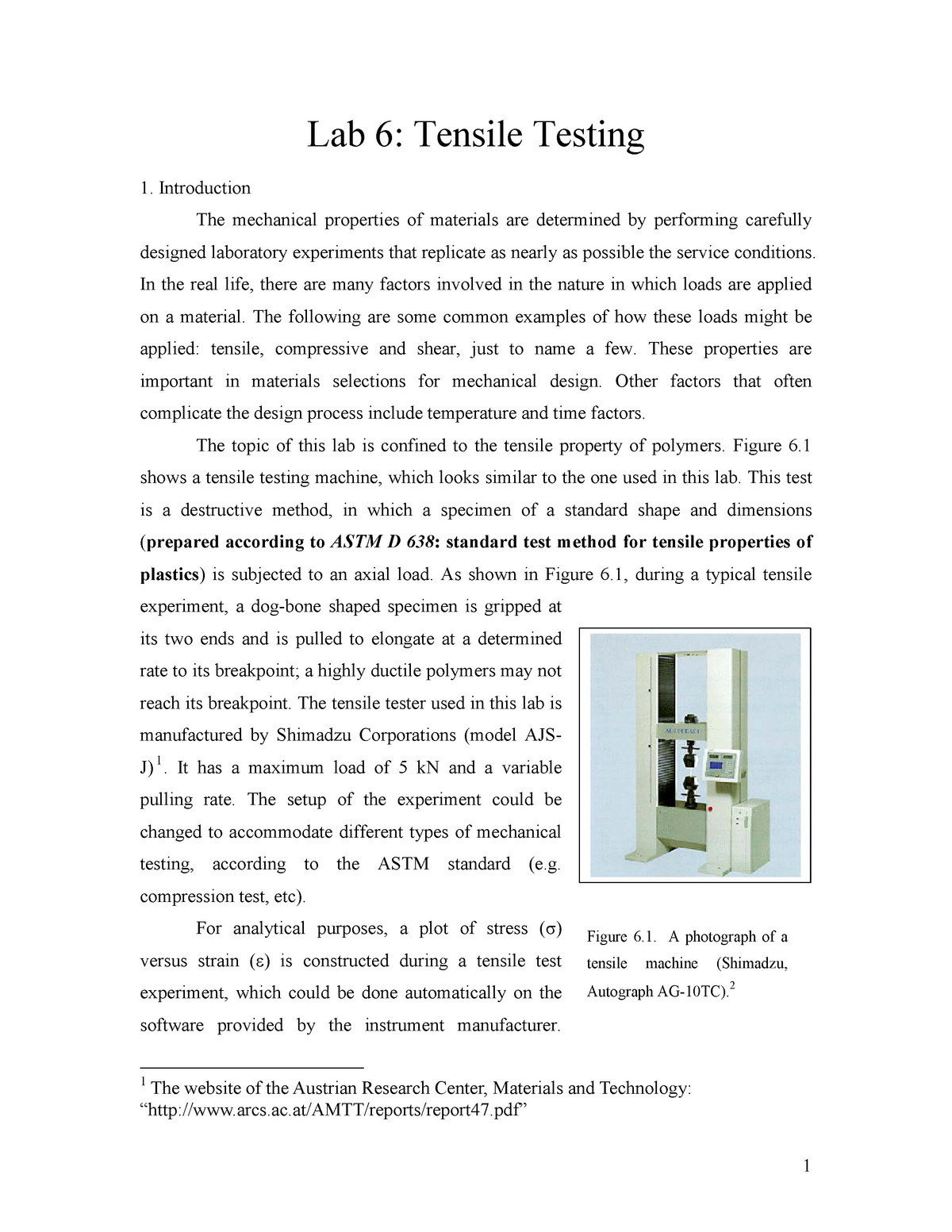

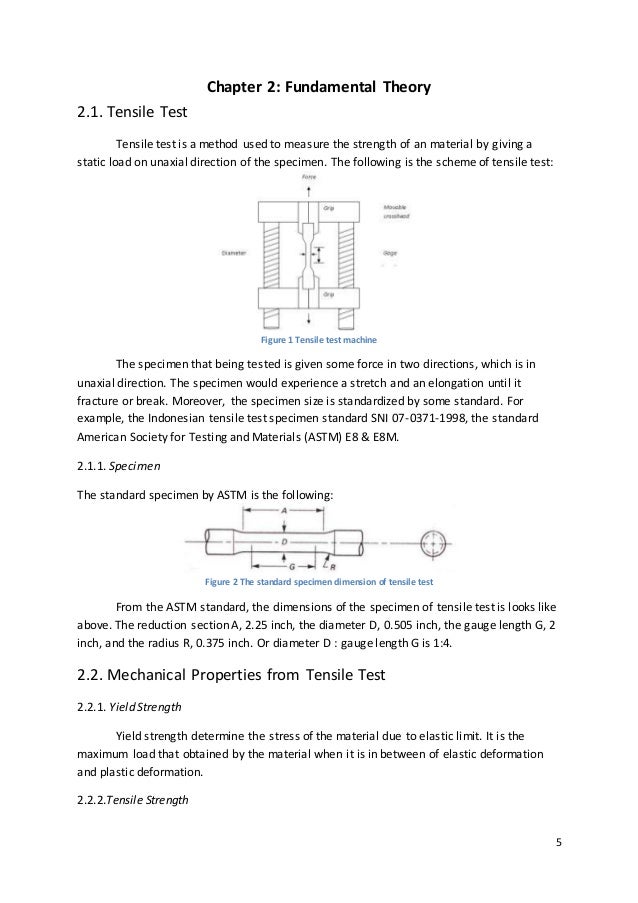

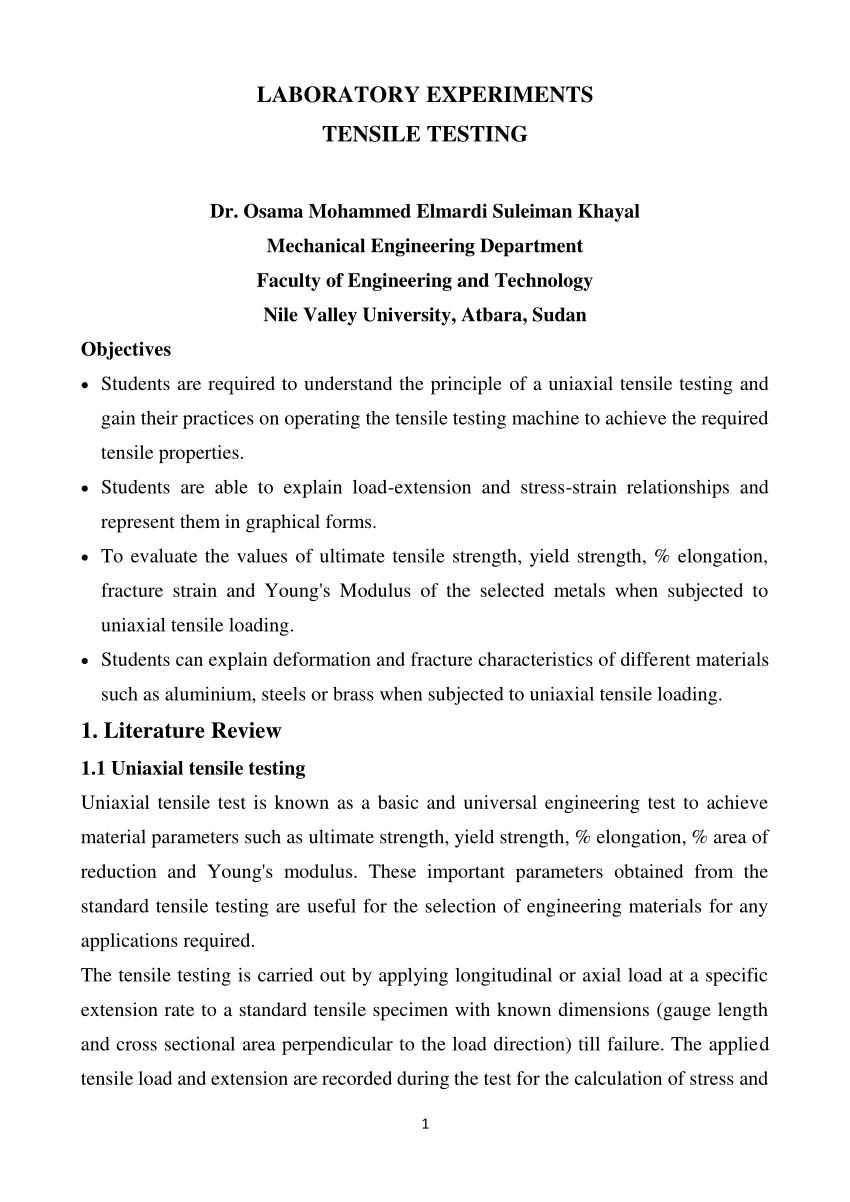

Tensile test lab report uitm. The basics on the operation of universal testing machine were also learnt during this experiment. Convenient sample geometry for the tensile test is the dogbone geometry figure 1. The tensile tester used in this lab is manufactured by shimadzu corporations model ajs j 1 it has a maximum load of 5 kn and a variable pulling rate. Percentage elongation and percentage reduction of area after fracture through data analysis for mild steel copper and aluminium by applying maximum load until it break.

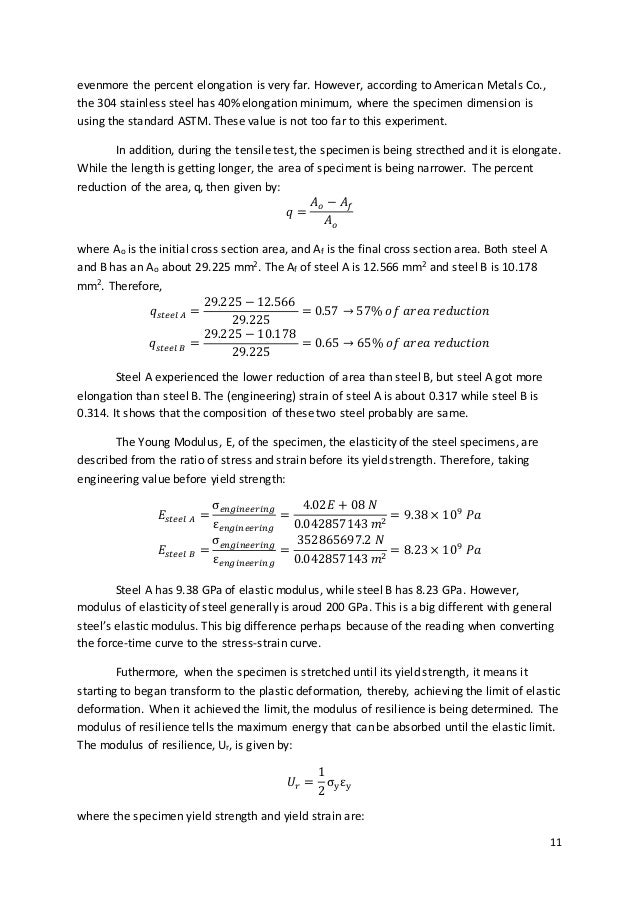

In this test geometry one end of σ f a 1 i i o i l l ε 2 σ eε 3 note. Bending in beam copy. The setup of the experiment could be changed to accommodate different types of mechanical testing according to the astm standard e g. Tensile test lab report free download as word doc doc docx pdf file pdf text file txt or read online for free.

Khurshidanjum pathan group a1a abstract. In this paper the author is reporting values as mean value standard deviation of the data. View test prep 180536084 tensile test uitm from mec 424 at mara university of technology. Tensile test lab report mae 361.

It had the highest ultimate tensile strength 527 9 mpa the greatest modulus of toughness 174 6 mpa and the largest true fracture strength 1047 mpa. The purpose of tensile test is to calculate tensile strength. For me lab i you will usually report your values as mean. The universal testing machine can be used to.

Tensile test report complete. Doc tensile test lab report peter namisi academia edu this experiment was conducted so as compare the mechanical properties of aluminium and mild steel. Mechanics of materials lab mec424 bending in beam mr. As a result it is possible to choose between the three different materials by the analysis and.

The results of the tensile tests showed that the a 36 hot rolled steel was the strongest material. The tensile test experiment can be used to determine other mechanical characteristics of the specimen like yield strength percentage elongation and ultimate strength among others. By measuring the force required to elongate a specimen to breaking point material properties can be determined that will allow designers and quality managers to predict how materials and products will behave in application.