Types Of Heat Exchangers Pdf

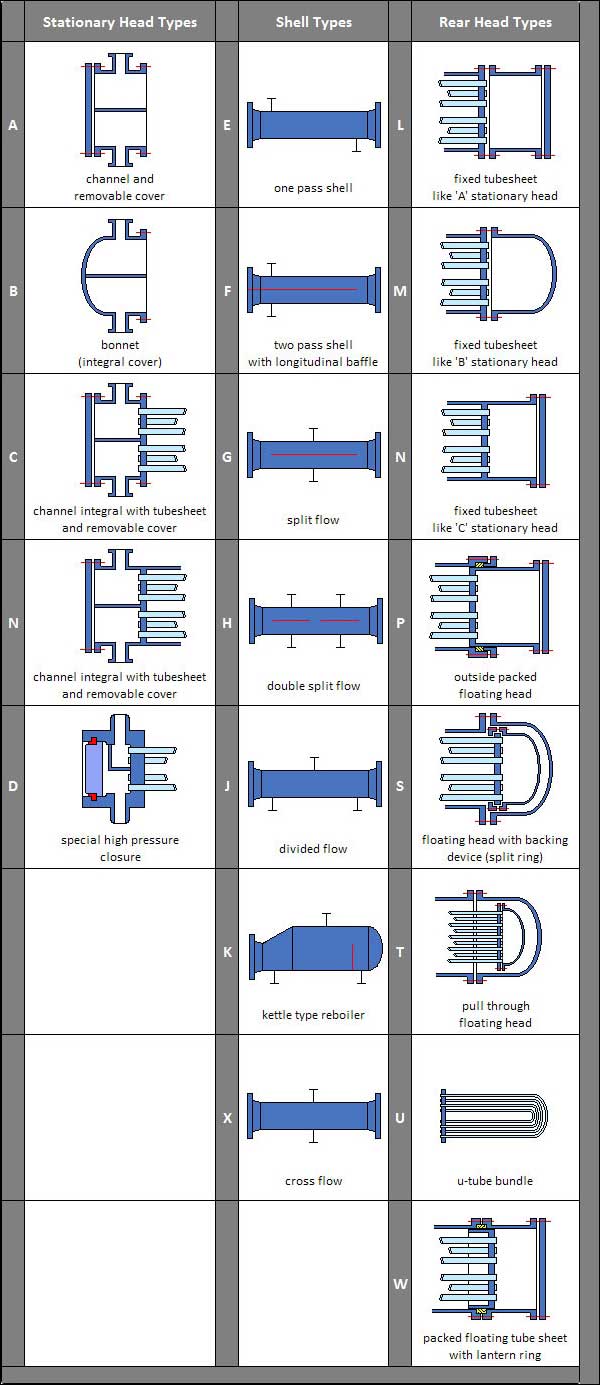

Different types of heat exchanger.

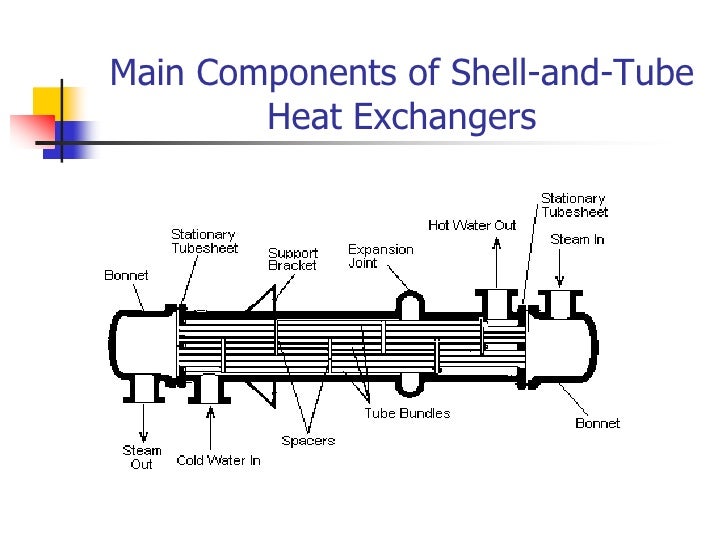

Types of heat exchangers pdf. A plate type heat exchanger as illustrated in figure 2 consists of plates instead of tubes to separate the hot and cold fluids. A fourth type of heat exchanger uses an intermediate fluid or solid store to hold heat which is then moved to the other side of the heat exchanger to be released. Tube and shell or plate. A heat exchanger is a heat transfer device that exchanges heat between two or more process fluids.

The hot and cold fluids alternate between each of the plates. Although the majority of heat exchangers used on chemical plant are shell and tube units there are many other types available. Double pipe heat exchanger one fluid flows through the smaller pipe while the other fluid flows through the annular space between the two pipes. This type of heat exchanger is designed to allow a large heat transfer surface area per unit volume.

Common examples of heat exchangers are shell and tube exchangers automobile radiators condensers evaporators air preheaters and cooling towers. Car radiator human lung am0ongest others. Heat exchangers have widespread industrial and domestic applications. The engineer may have little knowledge of the attributes of these other types so is not able to make a reasonable.

Heat exchangers doe hdbk 1018 1 93 types of heat exchangers. Heat exchangers with β 700 are classified as compact heat exchanger e g. Types of heat exchangers heat exchangers are classified according to flow arrangement and type of construction. The ratio of the heat transfer surface area of a heat exchanger to its volume is called the area density β.

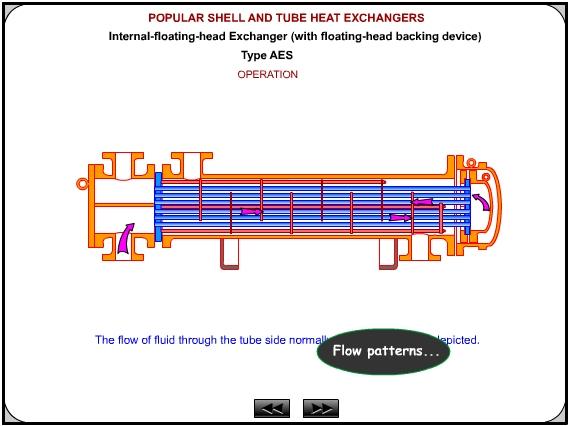

Two examples of this are adiabatic wheels which consist of a large wheel with fine threads rotating through the hot and cold fluids and fluid heat exchangers. They allow high. Baffles direct the flow of fluid between plates. Figure 1 tube and shell heat exchanger.

In terms of fluid flow through the heat exchanger recuperator regenerator or evaporative type. Although heat exchangers come in every shape and size imaginable the construction of most heat exchangers fall into one of two categories. These are water cooled condensers and. As in all mechanical devices each type has its advantages and disadvantages.