Liquid Liquid Extraction Column

A countercurrent extraction plant is used to extract acetone from its mixture with water by means of methyl isobutene ketone mik at a temperature of 25 c.

Liquid liquid extraction column. Koch modular has a variety of di. The first step of an extraction process is mixing for an intensive contact of both liquid phases to enable the mass transfer of the product white dots from the blue feed liquor into the yellow solvent. Liquid liquid or solvent extraction is a countercurrent separation process for isolating the constituents of a liquid mixture. Pure solvent is to be used and the column operates at 25ºc and the feed flow is 8 000 kg hr.

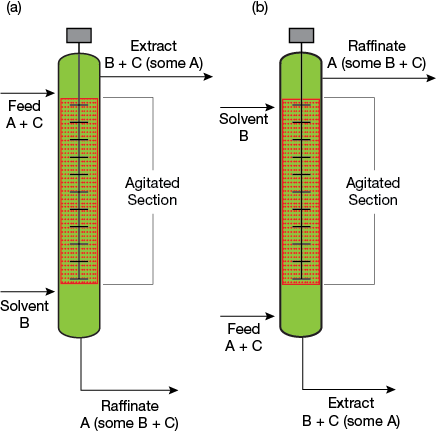

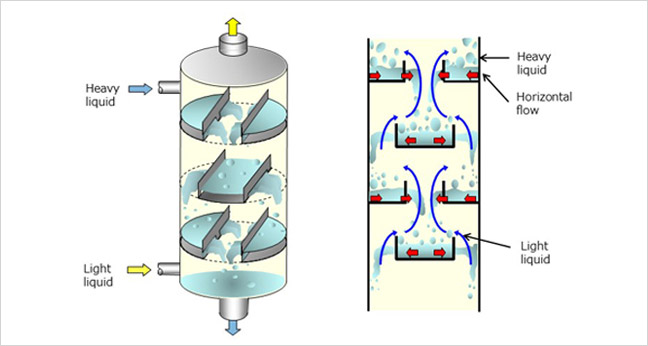

Of separation and application technologies amongst which liquid liquid extraction. Koch modular process systems demonstrate how one of its patented karr column designs functions for liquid liquid extraction. Agitated and static columns for liquid liquid extraction. It may be measured over an array of effective heights solvent to feed ratios and flow rates.

The more theoretical separation stages have to be realized the more an extraction column becomes economically interesting compared to mixer settlers since increasing the number of theoretical separation stages just increases the height of the column the 2 liquid phases pass the column by gravity in a counter current manner. The feed consists of 40 weight acetone and the balance water. Working principle liquid liquid extraction is an important separation technology with a wide range of applications in the modern process in dustry. However to avoid getting nothing for something and to drive towards fast inexpensive and selective lle protocols one really does need to put in a lot of method development effort.

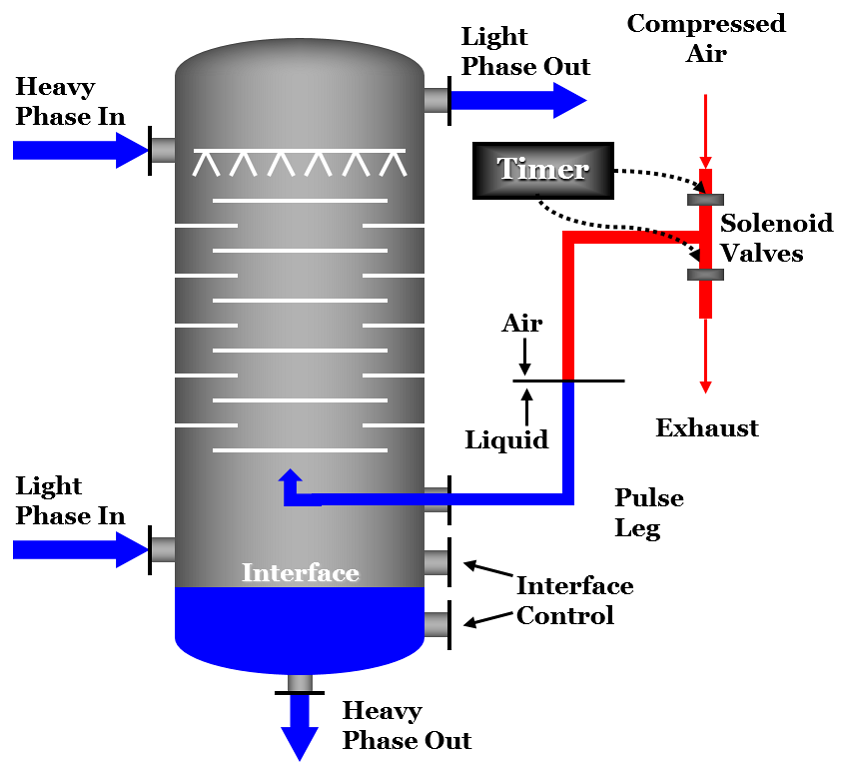

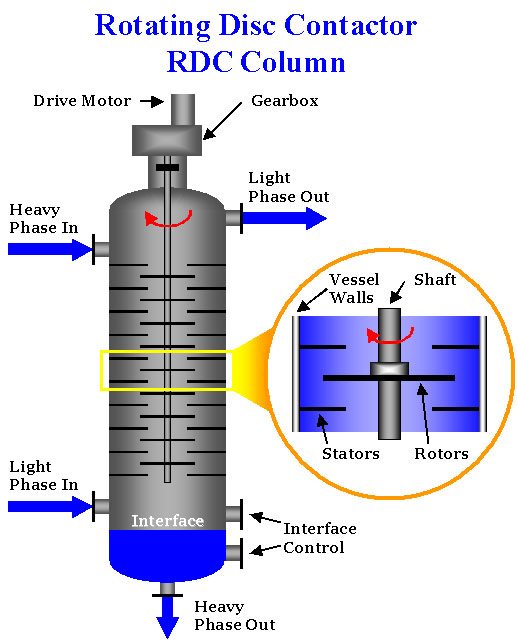

In its simplest form this involves the extraction of a solute from a binary solution by bringing it into contact with a second immiscible solvent in which the solute is soluble. Liquid liquid extraction also known as solvent extraction and partitioning is a method to separate compounds or metal complexes based on their relative solubilities in two different immiscible liquids usually water and an organic solvent. In addition to koch modular s signature karr columns and scheibel columns we also provide rotating disc contactors rdc pulsed columns and special designs for those in need of an agitated column design as well as sieve trays random packing and. There is a net transfer of one or more species from one liquid into another liquid phase generally from aqueous to organic.

It is useful to note that the agitation speed varies if the selected extractor is agitated. The extraction process is based on different solubilities of components in two. The second step is the phase separation or settling of the 2 liquid phases. As part of our liquid liquid extraction equipment koch modular has a wide range of extractors to choose from both static and agitated columns.

Once the transfer is complete the overall system of chemical components. In summary then there are many more considerations when designing a simple liquid liquid extraction experiment than one might realise. Selection scale up and design. The transfer is driven by chemical potential i e.